In addition to the development of hybrid (fusion) fibers, K-Tech Co., Ltd. is a producer of eco-friendly, high- performance coating yarns for industrial textiles, interior design, and industrial materials. Since its establishment in January 2019, it has pioneered the market through continuous research and development and has established a stable market. Recently, We entered the future car market by developing eco-friendly automotive fabrics. We are also expanding our business areas into 3D printing and carbon composite materials.

| Company | K-Tech Co., Ltd. | |||||||||

| CEO | Kim tae yeop | |||||||||

| Date | 2019.01.03 | |||||||||

| Main items |

Industrial fiber, machinery (mold, jig), prototype production, carbon composite material processing, etc. |

|||||||||

| Address |

|

| 2020.02. | Patent application for eco-friendly two-tone polyvinyl chloride coated yarn and its |

| 2021.02. | Patent registration for aramid coated yarn and its manufacturing method |

| 2021.09. | Patent application for fabric tape and its manufacturing method |

| 2021.12. | Gyeongsangbuk-do Startup Innovation Award |

Youth start-up as an eco-friendly coated yarn company

Certified as a disabled company

Venture business certification

Certification of corporate research institute

ISO 9001 certified

Established a factory in Gyeongsan-si, Gyeongsangbuk-do

| 1) | Fiber for automotive electronics |

| Development and production of functional fibers according to application areas such as shock absorption, heat resistance, and antifouling | |

| 2) | Building materials |

| Development and production of industrial fibers that satisfy customer needs such as heat resistance and insulation | |

| 3) | Textile for robot electronics |

| Development and production of functional fibers according to application areas such as shock absorption and sound absorption |

| 1) | Production of coated yarn by coating PET Nylon yarn with functional resin such as PVC and PC |

| 2) | Production of functional coated yarns such as special fiber aramid yarn and carbon fiber |

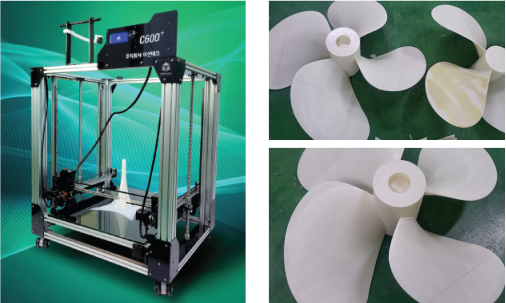

| 1) | Production of prototypes such as automobile parts Production of development prototypes with large 3D printer |

| 2) | Production of high-strength prototypes through 3D printing using carbon materials (automotive parts, etc.) |

| 1) | Carbon composite specimen layout design and production |

| 2) | Processing work such as cutting composite material specimens |

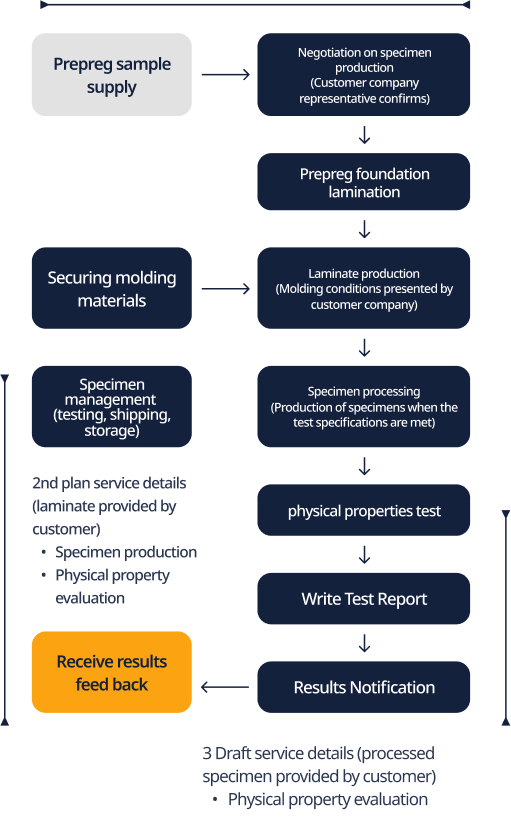

By analyzing the sample held, etc Conducting business consultations

After a detailed sample analysis Estimate progress

Based on a presentation estimate Consultation with the company

Coordinate production schedules and Delivery progress